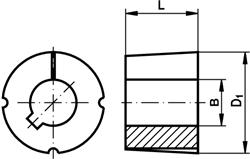

Trapezgewindemutter aus Werkstoff: EN 10277-3 11SMnPb37 – 1.0737 Trapezgewindemutter für Spannzwecke, besonders bequem, dank ihrer

sechskantiger Form. Geeignet zu Handanbetrieb mit mäßiger Belastung, da die Gleitpaarung Stahl-Stahl unter Belastung

zum Anfressen neigt. Das Material ist im Autogen-Verfahren schweißbar. Infolge des Blei-Gehaltes ist das Schweißen

mit Elektroden nicht zu empfehlen.

| Durchmesser |

E |

L |

Gewicht |

At |

| x Steigung |

mm |

mm |

ca. kg/St. |

mm² |

| Tr 10×3 |

17 |

15 |

0,021 |

240 |

| Tr 12×3 |

19 |

18 |

0,027 |

296 |

| Tr 14×4 |

22 |

21 |

0,044 |

395 |

| Tr 16×4 |

27 |

24 |

0,082 |

528 |

| Tr 18×4 |

27 |

27 |

0,084 |

553 |

| Tr 20×4 |

30 |

30 |

0,114 |

847 |

| Tr 22×5 |

30 |

33 |

0,112 |

1010 |

| Tr 24×5 |

36 |

36 |

0,200 |

1215 |

| Tr 26×5 |

36 |

39 |

0,193 |

1440 |

| Tr 28×5 |

41 |

42 |

0,291 |

1680 |

| Tr 30×6 |

46 |

45 |

0,420 |

1908 |

| Tr 32×6 |

46 |

48 |

0,411 |

2186 |

| Tr 36×6 |

55 |

54 |

0,706 |

2800 |

| Tr 40×7 |

65 |

60 |

1,172 |

3440 |

| Tr 44×7 |

65 |

66 |

1,159 |

4200 |

| Tr 50×8 |

75 |

75 |

1,783 |

5418 |

| Tr 60×9 |

90 |

90 |

3,087 |

7847 |

| Tr 70×10 |

90 |

105 |

2,837 |

10200 |

Trapezgewindemutter

trapezgewindemutter kunststoff

Trapezgewindemutter Kunststoff aus Werkstoff: PA 6 + Mo S2 DIN 7728 + Zusatzstoff Dieser Muttern werden aus sehr verschleissfestem Kunstoff gefertigt und sind perfekt dauergeschmiert. Eine Schmierung jeglicher Art ist über die gesamte Lebensdauer nicht nötig. Die Länge 3xTr

ermöglicht eine ausgezeichnete Verteilung der Belastung und folglich eine beschränkte Abnützung. Die Abmessungen der Flansche

gewährleisten eine perfekte Austauschbarkeit gegen die Typen FTN, FXN, HDL und HAL.(Nur die Gesamtlänge und die

Flanschdicke ändern sich).

| Durchmesser |

d1 |

d2 |

d3 |

d4 |

d5 |

p |

L |

s |

Anzahl der |

Befestigungs- |

Gewicht |

At |

| x Steigung |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

Befestigungs- bohrungen |

schrauben |

ca. kg/St. |

mm² |

| Tr 12×3 |

18 |

26 |

37 |

4,5 |

7,5 |

4,2 |

36 |

12 |

4 |

M4 |

0,016 |

594 |

| Tr 16×4 |

22 |

32 |

45 |

5,5 |

9,5 |

5,2 |

48 |

16 |

4 |

M5 |

0,030 |

1056 |

| Tr 20×4 |

30 |

40 |

52 |

5,5 |

9,5 |

5,2 |

60 |

20 |

4 |

M5 |

0,057 |

1696 |

| Tr 25×5 |

35 |

48 |

62 |

6,5 |

11 |

6,5 |

75 |

25 |

6 |

M6 |

0,094 |

2650 |

| Tr 28×5 |

40 |

53 |

68 |

6,5 |

11 |

6,5 |

90 |

30 |

6 |

M6 |

0,142 |

3600 |

| Tr 30×6 |

40 |

53 |

68 |

6,5 |

11 |

6,5 |

90 |

30 |

6 |

M6 |

0,135 |

3816 |

| Tr 35×6 |

50 |

63 |

78 |

8,5 |

14 |

8,5 |

105 |

35 |

6 |

M8 |

0,221 |

5277 |

| Tr 40×7 |

55 |

68 |

84 |

8,5 |

14 |

8,5 |

120 |

40 |

6 |

M8 |

0,289 |

6880 |

| Tr 40×10 |

55 |

68 |

84 |

8,5 |

14 |

8,5 |

120 |

40 |

6 |

M8 |

0,252 |

6597 |

| Tr 50×8 |

65 |

80 |

100 |

10,5 |

17 |

10,5 |

150 |

50 |

6 |

M10 |

0,476 |

10840 |

trapezgewindemutter kunststoff

Werkstoff: EN 1982 Cu Sn5 Zn5 Pb5-C – CC491K

Flanschmutter aus Bronze; dank der guten Verschleiss-Eigenschaften besonders geeignet für Dauerbetrieb. Eine gute

Schmierung ist ratsam.

| Durchmesser |

d1 |

d2 |

d3 |

d4 |

L |

S |

Anzahl der |

Befestigungs- |

Gewicht |

At |

| x Steigung |

mm |

mm |

mm |

mm |

mm |

mm |

Befestigungs- bohrungen |

schrauben |

ca. kg/St. |

mm² |

| Tr 10×2 |

25 |

34 |

42 |

5 |

25 |

10 |

6 |

M6 |

0,164 |

250 |

| Tr 12×3 |

28 |

38 |

48 |

6 |

35 |

12 |

6 |

M6 |

0,276 |

400 |

| Tr 14×3 |

28 |

38 |

48 |

6 |

35 |

12 |

6 |

M6 |

0,272 |

460 |

| Tr 16×4 |

28 |

38 |

48 |

6 |

35 |

12 |

6 |

M6 |

0,260 |

530 |

| Tr 18×4 |

28 |

38 |

48 |

6 |

35 |

12 |

6 |

M6 |

0,247 |

610 |

| Tr 20×4 |

32 |

45 |

55 |

7 |

44 |

12 |

6 |

M6 |

0,370 |

870 |

| Tr 22×5 |

32 |

45 |

55 |

7 |

44 |

12 |

6 |

M6 |

0,360 |

1030 |

| Tr 24×5 |

32 |

45 |

55 |

7 |

44 |

12 |

6 |

M6 |

0,337 |

1040 |

| Tr 26×5 |

38 |

50 |

62 |

7 |

46 |

14 |

6 |

M6 |

0,516 |

1280 |

| Tr 28×5 |

38 |

50 |

62 |

7 |

46 |

14 |

6 |

M6 |

0,472 |

1200 |

| Tr 30×6 |

38 |

50 |

62 |

7 |

46 |

14 |

6 |

M6 |

0,472 |

1370 |

| Tr 32×6 |

45 |

58 |

70 |

7 |

54 |

16 |

6 |

M6 |

0,779 |

1710 |

| Tr 36×6 |

45 |

58 |

70 |

7 |

54 |

16 |

6 |

M6 |

0,694 |

1950 |

| Tr 40×7 |

63 |

78 |

95 |

9 |

66 |

16 |

6 |

M6 |

1,788 |

2650 |

| Tr 44×7 |

63 |

78 |

95 |

9 |

66 |

16 |

6 |

M6 |

1,657 |

2940 |

| Tr 50×8 |

72 |

90 |

110 |

11 |

75 |

18 |

6 |

M6 |

2,500 |

4540 |

| Tr 60×9 |

88 |

110 |

130 |

13 |

90 |

20 |

6 |

M6 |

4,260 |

5490 |

| Tr 70×10 |

95 |

120 |

140 |

13 |

105 |

22 |

6 |

M6 |

5,303 |

7500 |

Werkstoff: EN 1982 Cu Sn12-C – CC483K

Flanschmutter aus Bronze, geeignet für Bewegungsantriebe mit mässiger Belastung im Vergleich zu den Typen FXN,

HDL und HAL. Eine gute Schmierung ist ratsam.

16

| Durchmesser |

d1 |

d2 |

d3 |

d4 |

d5 |

p |

L |

s |

Anzahl der |

Befestigungs- |

Gewicht |

At |

| x Steigung |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

Befestigungs- bohrungen |

schrauben |

ca. kg/St. |

mm² |

| Tr 10×3 |

16 |

24 |

32 |

4,5 |

7,5 |

4,2 |

20 |

8 |

3 |

M4 |

0,062 |

267 |

| Tr 12×3 |

18 |

26 |

35 |

4,5 |

7,5 |

4,2 |

22 |

8 |

4 |

M4 |

0,074 |

362 |

| Tr 14×4 |

20 |

30 |

40 |

5,5 |

9,5 |

5,2 |

25 |

10 |

4 |

M5 |

0,111 |

470 |

| Tr 16×4 |

22 |

32 |

42 |

5,5 |

9,5 |

5,2 |

30 |

10 |

4 |

M5 |

0,131 |

660 |

| Tr 18×4 |

25 |

35 |

45 |

5,5 |

9,5 |

5,2 |

35 |

10 |

4 |

M5 |

0,168 |

880 |

| Tr 20×4 |

30 |

40 |

50 |

5,5 |

9,5 |

5,2 |

40 |

10 |

5 |

M5 |

0,248 |

1130 |

| Tr 25×5 |

35 |

48 |

60 |

6,5 |

11 |

6,5 |

45 |

12 |

5 |

M5 |

0,380 |

1590 |

| Tr 28×5 |

40 |

53 |

65 |

6,5 |

11 |

6,5 |

50 |

12 |

5 |

M6 |

0,505 |

2000 |

| Tr 30×6 |

50 |

53 |

65 |

6,5 |

11 |

6,5 |

50 |

12 |

5 |

M6 |

0,470 |

2120 |

| TR 35×6 |

50 |

63 |

75 |

6,5 |

11 |

6,5 |

60 |

12 |

6 |

M6 |

0,815 |

3015 |

| Tr 36×6 |

50 |

63 |

75 |

6,5 |

11 |

6,5 |

60 |

12 |

6 |

M6 |

0,786 |

3110 |

| Tr 40×7 |

55 |

68 |

80 |

6,5 |

11 |

6,5 |

65 |

12 |

6 |

M6 |

0,971 |

3727 |

| Tr 45×8 |

60 |

73 |

85 |

6,5 |

11 |

6,5 |

80 |

12 |

8 |

M6 |

1,254 |

5152 |

| Tr 50×8 |

65 |

78 |

90 |

6,5 |

11 |

6,5 |

80 |

12 |

8 |

M6 |

1,372 |

5780 |

| Tr 55×9 |

70 |

85 |

100 |

8,5 |

14 |

8,5 |

95 |

15 |

6 |

M8 |

1,893 |

7534 |

| Tr 60×9 |

75 |

90 |

105 |

8,5 |

14 |

8,5 |

95 |

15 |

6 |

M8 |

2,042 |

8282 |

| Tr 70×10 |

90 |

105 |

120 |

8,5 |

14 |

8,5 |

120 |

18 |

8 |

M8 |

3,715 |

8742 |

| Tr 80×10 |

100 |

115 |

130 |

8,5 |

14 |

8,5 |

120 |

18 |

8 |

M8 |

4,178 |

14137 |

Werkstoff: EN 1982 Cu Sn12-C – CC483K

Flanschmutter aus Bronze mit aussergewöhnlicher Länge (3xTr), geeignet für hohe Belastungen

und / oder hohe Verfahrgeschwindigkeit. Die besondere Länge 3xTr bewirkt einen nur geringen Verschleiss. Eine gute

Schmierung ist ratsam. Die Abmessungen der Flansche gewährleisten eine perfekte Austauschbarkeit gegen die Typen

FTN, FXN, HAL und FCS.(Nur die Gesamtlänge und die Flanschdicke ändern sich).

| Durchmesser |

d1 |

d2 |

d3 |

d4 |

d5 |

p |

L |

s |

Anzahl der |

Befestigungs- |

Gewicht |

At |

| x Steigung |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

Befestigungs- bohrungen |

schrauben |

ca. kg/St. |

mm² |

| Tr 14×4 |

20 |

30 |

42 |

5,5 |

9,5 |

5,2 |

42 |

10 |

4 |

M5 |

0,151 |

790 |

| Tr 16×4 |

22 |

32 |

45 |

5,5 |

9,5 |

5,2 |

48 |

10 |

4 |

M5 |

0,183 |

1056 |

| Tr 18×4 |

25 |

35 |

48 |

5,5 |

9,5 |

5,2 |

54 |

10 |

4 |

M5 |

0,233 |

1356 |

| Tr 20×4 |

30 |

40 |

52 |

5,5 |

9,5 |

5,2 |

60 |

12 |

4 |

M5 |

0,368 |

1696 |

| Tr 22×5 |

30 |

40 |

52 |

5,5 |

9,5 |

5,2 |

60 |

12 |

4 |

M5 |

0,338 |

1838 |

| Tr 25×5 |

35 |

48 |

62 |

6,5 |

11 |

6,5 |

75 |

15 |

6 |

M6 |

0,586 |

2650 |

| Tr 28×5 |

40 |

53 |

68 |

6,5 |

11 |

6,5 |

90 |

18 |

6 |

M6 |

0,903 |

3600 |

| Tr 30×6 |

40 |

53 |

68 |

6,5 |

11 |

6,5 |

90 |

18 |

6 |

M6 |

0,841 |

3816 |

| Tr 30×3 |

40 |

53 |

68 |

6,5 |

11 |

6,5 |

90 |

18 |

6 |

M6 |

0,784 |

3816 |

| Tr 32×6 |

40 |

53 |

68 |

6,5 |

11 |

6,5 |

90 |

18 |

6 |

M6 |

0,765 |

4100 |

| Tr 35×6 |

50 |

63 |

63 |

8,5 |

14 |

8,5 |

105 |

20 |

6 |

M8 |

1,439 |

5277 |

| Tr 40×7 |

55 |

68 |

68 |

8,5 |

14 |

8,5 |

120 |

25 |

6 |

M8 |

1,937 |

6880 |

| Tr 40×10 |

55 |

68 |

68 |

8,5 |

14 |

8,5 |

120 |

25 |

6 |

M8 |

1,986 |

6597 |

| Tr 40×4 |

55 |

68 |

68 |

8,5 |

14 |

8,5 |

120 |

25 |

6 |

M8 |

1,929 |

6597 |

| Tr 50×6 |

65 |

80 |

80 |

10,5 |

17 |

10,5 |

150 |

30 |

6 |

M10 |

3,007 |

10840 |

| Tr 50×8 |

65 |

80 |

80 |

10,5 |

17 |

10,5 |

150 |

30 |

6 |

M10 |

3,075 |

10840 |

| Tr 50×10 |

65 |

80 |

80 |

10,5 |

17 |

10,5 |

150 |

30 |

6 |

M10 |

3,127 |

10600 |

| Tr 60×9 |

75 |

95 |

95 |

12,5 |

19 |

12,5 |

180 |

35 |

6 |

M12 |

4,797 |

15700 |

Werkstoff: EN 1982 Cu Sn12-C – CC483K

Flanschmutter aus Zinnbronze; dank der guten Verschleiss-Eigenschaften besonders geeignet für Dauerbetrieb. Eine gute

Schmierung ist ratsam.

| Durchmesser |

d1 |

d2 |

d3 |

d4 |

d5 |

p |

L |

s |

Anzahl der |

Befestigungs- |

Gewicht |

At |

| x Steigung |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

Befestigungs- bohrungen |

schrauben |

ca. kg/St. |

mm² |

| Tr 10×3 |

18 |

26 |

37 |

4,5 |

7,5 |

4,2 |

22 |

8 |

4 |

M4 |

0,088 |

294 |

| Tr 12×3 |

18 |

26 |

37 |

4,5 |

7,5 |

4,2 |

22 |

8 |

4 |

M4 |

0,082 |

362 |

| Tr 14×4 |

20 |

30 |

42 |

5,5 |

9,5 |

5,2 |

25 |

10 |

4 |

M5 |

0,123 |

470 |

| Tr 16×4 |

22 |

32 |

45 |

5,5 |

9,5 |

5,2 |

30 |

10 |

4 |

M5 |

0,149 |

660 |

| Tr 18×4 |

25 |

35 |

48 |

5,5 |

9,5 |

5,2 |

35 |

10 |

4 |

M5 |

0,188 |

880 |

| Tr 20×4 |

30 |

40 |

52 |

5,5 |

9,5 |

5,2 |

40 |

10 |

5 |

M5 |

0,263 |

1130 |

| Tr 22×5 |

30 |

40 |

52 |

5,5 |

9,5 |

5,2 |

40 |

10 |

5 |

M5 |

0,244 |

1225 |

| Tr 25×5 |

35 |

48 |

62 |

6,5 |

11 |

6,5 |

45 |

12 |

5 |

M6 |

0,386 |

1590 |

| Tr 28×5 |

40 |

53 |

68 |

6,5 |

11 |

6,5 |

50 |

12 |

5 |

M6 |

05,38 |

2000 |

| Tr 30×6 |

40 |

53 |

68 |

6,5 |

11 |

6,5 |

50 |

12 |

5 |

M6 |

0,504 |

2120 |

| Tr 35×6 |

50 |

63 |

78 |

6,5 |

11 |

6,5 |

60 |

12 |

6 |

M6 |

0,872 |

3015 |

| Tr 36×6 |

50 |

63 |

78 |

6,5 |

11 |

6,5 |

60 |

12 |

6 |

M6 |

0,845 |

3110 |

| Tr 40×7 |

55 |

68 |

84 |

6,5 |

11 |

6,5 |

65 |

12 |

6 |

M6 |

1,059 |

3727 |

| Tr 45×8 |

55 |

72 |

90 |

8,5 |

14 |

8,5 |

65 |

15 |

6 |

M8 |

0,999 |

4186 |

| Tr 50×8 |

65 |

80 |

100 |

8,5 |

14 |

8,5 |

80 |

15 |

6 |

M8 |

1,679 |

5780 |

| Tr 55×9 |

70 |

95 |

120 |

10,5 |

17 |

10,5 |

80 |

18 |

6 |

M10 |

2,325 |

6345 |

| Tr 60×9 |

75 |

95 |

120 |

10,5 |

17 |

10,5 |

100 |

18 |

6 |

M10 |

2,701 |

8718 |

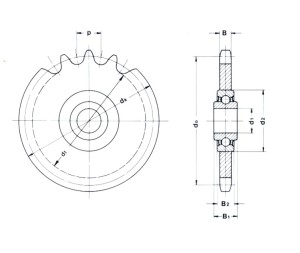

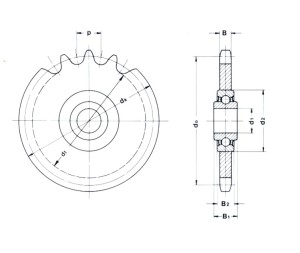

- Sprocket for Chain 081-1

- number of teethl= 12

- with assembled brass-thread-bush

- special manufactured according to drawing

Werkstoff: PA 6 + Mo S2 DIN 7728 Diese zylindrische Kunststoff-Mutter ist sehr verschleissfest und geeignet für mässige

und mittlere Belastungen. Um eine lange Lebensdauer der Muttern MPH zu gewährleisten, ist eine gelegentliche Schmierung mit Fett

oder Oel nötig. (Keine Schmiermittel mit Molybden-Bisolfur MoS2 oder Grafit verwenden).

Diese Kunststoff-Muttern sind ausschliesslich in Verbindung mit unseren gewalzten Präzisions-Gewindespindeln einzusetzen, deren Rauhigkeit und

Oberflächenhärte speziell geeignet sind. Der Einsatz der Muttern FCS auf geschnittenen Spindeln ist nicht möglich. Besondere Beachtung ist den

hygroskopischen Eigenschaften dieses Materials zu widmen. Infolge beachtlicher Massänderungen durch Feuchtigkeit am Einsatzort ist die

Verwendung für Präzisionsantriebe nicht zu empfehlen.

| Durchmesser |

d |

L |

Gewicht |

At |

| x Steigung |

mm |

mm |

ca. kg/St. |

mm² |

| Tr 12×3 |

26 |

24 |

0,012 |

396 |

| Tr 16×4 |

36 |

32 |

0,030 |

704 |

| Tr 20×4 |

45 |

40 |

0,060 |

1130 |

| Tr 25×5 |

50 |

48 |

0,083 |

1696 |

| Tr 28×5 |

60 |

60 |

0,154 |

2400 |

| Tr 30×6 |

60 |

60 |

0,150 |

2544 |

| Tr 35×6 |

75 |

72 |

0,290 |

3618 |

| Tr 40×7 |

80 |

80 |

0,355 |

4587 |

| Tr 50×8 |

90 |

100 |

0,523 |

7225 |

Werkstoff: EN 1982 Cu Sn12-C – CC483K

Flanschmutter aus Zinnbronze; dank der guten Verschleiss-Eigenschaften besonders geeignet für Dauerbetrieb. Eine gute

Schmierung ist ratsam. Die Abmessungen der Flansche gewährleisten eine perfekte Austauschbarkeit gegen die Typen

FTN, HDL, HAL und FCS. (Nur die Gesamtlänge und die Flanschdicke ändern sich).

| Durchmesser |

d1 |

d2 |

d3 |

d4 |

d5 |

p |

L |

s |

Anzahl der |

Befestigungs- |

Gewicht |

At |

| x Steigung |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

Befestiguns- bohrungen |

schrauben |

ca. kg/St. |

mm² |

| Tr 10×3 |

18 |

26 |

37 |

4,5 |

7,5 |

4,2 |

22 |

8 |

4 |

M4 |

0,088 |

294 |

| Tr 12×3 |

18 |

26 |

37 |

4,5 |

7,5 |

4,2 |

22 |

8 |

4 |

M4 |

0,082 |

362 |

| Tr 14×4 |

20 |

30 |

42 |

5,5 |

9,5 |

5,2 |

25 |

10 |

4 |

M5 |

0,123 |

470 |

| Tr 16×4 |

22 |

32 |

45 |

5,5 |

9,5 |

5,2 |

25 |

10 |

4 |

M5 |

0,149 |

660 |

| Tr 18×4 |

25 |

35 |

48 |

5,5 |

9,5 |

5,2 |

30 |

10 |

4 |

M5 |

0,188 |

880 |

| Tr 20×4 |

30 |

40 |

52 |

5,5 |

9,5 |

5,2 |

35 |

10 |

4 |

M5 |

0,267 |

1130 |

| Tr 22×5 |

30 |

40 |

52 |

5,5 |

9,5 |

5,2 |

40 |

10 |

4 |

M5 |

0,247 |

1225 |

| Tr 24×5 |

35 |

48 |

62 |

6,5 |

11 |

6,5 |

45 |

12 |

6 |

M6 |

0,408 |

1520 |

| Tr 25×5 |

35 |

48 |

62 |

6,5 |

11 |

6,5 |

45 |

12 |

6 |

M6 |

0,393 |

1590 |

| Tr 26×5 |

35 |

48 |

62 |

6,5 |

11 |

6,5 |

45 |

12 |

6 |

M6 |

0,378 |

1660 |

| Tr 28×5 |

40 |

53 |

68 |

6,5 |

11 |

6,5 |

50 |

12 |

6 |

M6 |

0,532 |

2000 |

| Tr 30×6 |

40 |

53 |

68 |

6,5 |

11 |

6,5 |

50 |

12 |

6 |

M6 |

0,497 |

2120 |

| Tr 32×6 |

40 |

53 |

68 |

6,5 |

11 |

6,5 |

50 |

12 |

6 |

M6 |

0,455 |

2277 |

| Tr 35×6 |

50 |

63 |

78 |

8,5 |

14 |

8,5 |

60 |

15 |

6 |

M8 |

0,883 |

3015 |

| Tr 36×6 |

50 |

63 |

78 |

8,5 |

14 |

8,5 |

60 |

15 |

6 |

M8 |

0,854 |

3110 |

| Tr 40×7 |

55 |

68 |

84 |

8,5 |

14 |

8,5 |

65 |

15 |

6 |

M8 |

1,066 |

3727 |

| Tr 44×7 |

55 |

72 |

90 |

8,5 |

14 |

8,5 |

65 |

15 |

6 |

M8 |

1,029 |

4135 |

| Tr 45×8 |

55 |

72 |

90 |

8,5 |

14 |

8,5 |

65 |

15 |

6 |

M8 |

0,999 |

4186 |

| Tr 50×8 |

65 |

80 |

100 |

10,5 |

17 |

10,5 |

80 |

20 |

6 |

M10 |

1,749 |

5780 |

| Tr 55×9 |

65 |

80 |

100 |

10,5 |

17 |

10,5 |

80 |

20 |

6 |

M10 |

1,475 |

6345 |

| Tr 60×9 |

75 |

95 |

120 |

12,5 |

19 |

12,5 |

100 |

25 |

6 |

M12 |

2,927 |

8718 |

Werkstoff: EN 1982 Cu Sn5 Zn5 Pb5-C – CC491K

Flanschmutter aus Bronze, geeignet für Bewegungsantriebe mit mässiger Belastung im Vergleich zu den Typen FXN,

HDL und HAL. Eine gute Schmierung ist ratsam. Die Abmessungen der Flansche gewährleisten eine perfekte

Austauschbarkeit gegen die Typen FXN, HDL, HAL und FCS. (Nur die Gesamtlänge und die Flanschdicke ändern sich).

| Durchmesser |

d1 |

d2 |

d3 |

d4 |

d5 |

p |

L |

s |

Anzahl der |

Befestigungs- |

Gewicht |

At |

| x Steigung |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

Befestiguns- bohrungen |

schrauben |

ca. kg/St. |

mm² |

| Tr 10×3 |

18 |

26 |

37 |

4,5 |

7,5 |

4,2 |

22 |

8 |

4 |

M4 |

0,088 |

294 |

| Tr 12×3 |

18 |

26 |

37 |

4,5 |

7,5 |

4,2 |

22 |

8 |

4 |

M4 |

0,082 |

362 |

| Tr 14×4 |

20 |

30 |

42 |

5,5 |

9,5 |

5,2 |

25 |

10 |

4 |

M5 |

0,123 |

470 |

| Tr 16×4 |

22 |

32 |

45 |

5,5 |

9,5 |

5,2 |

30 |

10 |

4 |

M5 |

0,149 |

660 |

| Tr 18×4 |

25 |

35 |

48 |

5,5 |

9,5 |

5,2 |

35 |

10 |

4 |

M5 |

0,188 |

880 |

| Tr 20×4 |

30 |

40 |

52 |

5,5 |

9,5 |

5,2 |

40 |

12 |

4 |

M5 |

0,267 |

1130 |

| Tr 22×5 |

30 |

40 |

52 |

5,5 |

9,5 |

5,2 |

40 |

12 |

4 |

M5 |

0,247 |

1225 |

| Tr 25×5 |

35 |

48 |

62 |

6,5 |

11 |

6,5 |

45 |

12 |

6 |

M6 |

0,393 |

1590 |

| Tr 28×5 |

40 |

53 |

68 |

6,5 |

11 |

6,5 |

50 |

12 |

6 |

M6 |

0,532 |

2000 |

| Tr 30×3 |

40 |

53 |

68 |

6,5 |

11 |

6,5 |

50 |

12 |

6 |

M6 |

0,482 |

2238 |

| Tr 30×4 |

40 |

53 |

68 |

6,5 |

11 |

6,5 |

50 |

12 |

6 |

M6 |

0,487 |

2200 |

| Tr 30×5 |

40 |

53 |

68 |

6,5 |

11 |

6,5 |

50 |

12 |

6 |

M6 |

0,492 |

2160 |

| Tr 30×6 |

40 |

53 |

68 |

6,5 |

11 |

6,5 |

50 |

12 |

6 |

M6 |

0,497 |

2120 |

| Tr 35×3 |

50 |

63 |

78 |

8,5 |

14 |

8,5 |

60 |

15 |

6 |

M8 |

0,862 |

3160 |

| Tr 35×4 |

50 |

63 |

78 |

8,5 |

14 |

8,5 |

60 |

15 |

6 |

M8 |

0,869 |

3110 |

| Tr 35×5 |

50 |

63 |

78 |

8,5 |

14 |

8,5 |

60 |

15 |

6 |

M8 |

0,876 |

3060 |

| Tr 35×6 |

50 |

63 |

78 |

8,5 |

14 |

8,5 |

60 |

15 |

6 |

M8 |

0,883 |

3015 |

| Tr 35×8 |

50 |

63 |

78 |

8,5 |

14 |

8,5 |

60 |

15 |

6 |

M8 |

0,898 |

2920 |

| Tr 40×3 |

55 |

68 |

84 |

8,5 |

14 |

8,5 |

60 |

15 |

6 |

M8 |

1,030 |

3930 |

| Tr 40×4 |

55 |

68 |

84 |

8,5 |

14 |

8,5 |

65 |

15 |

6 |

M8 |

1,039 |

3880 |

| Tr 40×5 |

55 |

68 |

84 |

8,5 |

14 |

8,5 |

65 |

15 |

6 |

M8 |

1,048 |

3828 |

| Tr 40×6 |

55 |

68 |

84 |

8,5 |

14 |

8,5 |

65 |

15 |

6 |

M8 |

1,057 |

3778 |

| Tr 40×7 |

55 |

68 |

84 |

8,5 |

14 |

8,5 |

65 |

15 |

6 |

M8 |

1,066 |

3727 |

| Tr 40×8 |

55 |

68 |

84 |

8,5 |

14 |

8,5 |

65 |

15 |

6 |

M8 |

1,075 |

3675 |

| Tr 45×8 |

55 |

72 |

90 |

8,5 |

14 |

8,5 |

65 |

15 |

6 |

M8 |

0,999 |

4186 |

| Tr 50×3 |

65 |

80 |

100 |

10,5 |

17 |

10,5 |

80 |

20 |

6 |

M10 |

1,679 |

6095 |

| Tr 50×4 |

65 |

80 |

100 |

10,5 |

17 |

10,5 |

80 |

20 |

6 |

M10 |

1,693 |

6030 |

| Tr 50×5 |

65 |

80 |

100 |

10,5 |

17 |

10,5 |

80 |

20 |

6 |

M10 |

1,707 |

5970 |

| Tr 50×6 |

65 |

80 |

100 |

10,5 |

17 |

10,5 |

80 |

20 |

6 |

M10 |

1,721 |

5905 |

| Tr 50×8 |

65 |

80 |

100 |

10,5 |

17 |

10,5 |

80 |

20 |

6 |

M10 |

1,749 |

5780 |

| Tr 55×9 |

65 |

80 |

100 |

10,5 |

17 |

10,5 |

80 |

20 |

6 |

M10 |

1,475 |

6345 |

| Tr 60×6 |

75 |

95 |

120 |

12,5 |

19 |

12,5 |

100 |

25 |

6 |

M12 |

2,865 |

8950 |

| Tr 60×7 |

75 |

95 |

120 |

12,5 |

19 |

12,5 |

100 |

25 |

6 |

M12 |

2,886 |

8875 |

| Tr 60×9 |

75 |

95 |

120 |

12,5 |

19 |

12,5 |

100 |

25 |

6 |

M12 |

2,927 |

8718 |

Werkstoff: EN 1982 Cu Sn12-C – CC483K

Mutter aus Zinnbronze geeignet für Bewegungsantriebe mit mäßiger Belastung.

Empfohlene für die Bequemlichkeit der Befestigung und die Verschleißfestigkeit.

| Durchmesser |

S |

L |

a |

b |

c |

d |

e |

Zylinderschraube |

Gewicht |

At |

| x Steigung |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mit Innensechskant |

ca. kg/St. |

mm² |

| Tr 16×4 |

35 |

40 |

26 |

24 |

5,2 |

5 |

9,5 |

M5 |

0,222 |

770 |

| Tr 20×4 |

40 |

50 |

38 |

28 |

6,5 |

6 |

10,0 |

M6 |

0,576 |

1412 |

| Tr 25×5 |

45 |

55 |

40 |

33 |

6,5 |

6 |

10,0 |

M6 |

0,761 |

1943 |

| Tr 30×6 |

50 |

60 |

49 |

38 |

6,5 |

6 |

10,0 |

M6 |

0,977 |

2544 |

| Tr 40×7 |

60 |

75 |

55 |

49 |

8,5 |

8 |

9,9 |

M8 |

1,608 |

4013 |

Werkstoff: EN 10277-3 11 S Mn Pb 37 – 1.0737

Gewindemutter für Spannzwecke und Verstellbewegungen im Handtrieb bei unbedeutender Belastung, da die

Gleitpaarung Stahl-Stahl unter Belastung zum Anfressen neigt.

| Durchmesser |

S |

L |

a |

b |

c |

d |

e |

Zylinderschraube |

Gewicht |

At |

| x Steigung |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mit Innensechskant |

ca. kg/St. |

mm² |

| Tr 12×3 |

25 |

30 |

20 |

17 |

4,2 |

4 |

7,0 |

M4 |

0,123 |

739 |

| Tr 14×4 |

30 |

35 |

24 |

20 |

5,2 |

5 |

9,5 |

M5 |

0,211 |

658 |

| Tr 16×4 |

35 |

40 |

24 |

21 |

5,2 |

5 |

9,5 |

M5 |

0,199 |

770 |

| Tr 18×4 |

35 |

45 |

26 |

24 |

6,5 |

6 |

10,0 |

M6 |

0,353 |

1131 |

| Tr 20×4 |

40 |

50 |

38 |

28 |

6,5 |

6 |

10,0 |

M6 |

0,517 |

1412 |

| Tr 25×5 |

45 |

55 |

40 |

33 |

6,5 |

6 |

10,0 |

M6 |

0,683 |

1943 |

| Tr 30×6 |

50 |

60 |

48 |

38 |

6,5 |

6 |

10,0 |

M6 |

0,877 |

2544 |

| Tr 35×6 |

60 |

70 |

55 |

45 |

8,5 |

8 |

13,0 |

M8 |

1,494 |

3517 |

| Tr 40×7 |

60 |

70 |

55 |

49 |

8,5 |

8 |

9,9 |

M8 |

1,347 |

4013 |

| Tr 50×8 |

70 |

90 |

70 |

60 |

8,5 |

8 |

9,9 |

M8 |

2,183 |

6502 |

| Tr 60×9 |

80 |

100 |

80 |

69 |

8,5 |

8 |

9,9 |

M8 |

2,990 |

8718 |

Werkstoff: EN 12164 CW614N-M

Anwendung für Bewegungsantriebe mit mässiger Belastung, da Messing nur beschränkte Belastungen aufnehmen kann

und nicht sehr verschleissfest ist.

| Durchmesser |

d |

L |

Gewicht |

At |

| x Steigung |

mm |

mm |

ca. kg/St. |

mm² |

| Tr 10×3 |

25 |

20 |

0,094 |

320 |

| Tr 12×3 |

25 |

25 |

0,110 |

411 |

| Tr 14×4 |

30 |

35 |

0,224 |

658 |

| Tr 16×4 |

30 |

35 |

0,212 |

770 |

| Tr 18×4 |

35 |

45 |

0,379 |

1131 |

| Tr 20×4 |

40 |

50 |

0,554 |

1412 |

| Tr 24×5 |

45 |

55 |

0,735 |

1943 |

| Tr 30×6 |

50 |

60 |

0,952 |

2544 |

| Tr 35×6 |

60 |

70 |

1,617 |

3517 |

| Tr 36×6 |

60 |

70 |

1,563 |

3630 |

| Tr 40×7 |

60 |

70 |

1,465 |

4013 |

-

-

SONY DSC

-

-

SONY DSC

-

-

SONY DSC

-

-

SONY DSC

-

-

SONY DSC

-

-

SONY DSC

-

-

SONY DSC

-

-

SONY DSC

Werkstoff: EN 10277-3 11 S Mn Pb 37 – 1.0737

Gewindemutter für Spannzwecke und Verstellbewegungen im Handbetrieb bei unbedeutender Belastung, da die

Gleitpaarung Stahl-Stahl unter Belastung zum Anfressen neigt. Das Material ist im MIG-MAG-Verfahren schweissbar

(mit Draht). Infolge des Blei-Gehaltes ist das Schweissen mit Elektroden nicht zu empfehlen.

| Durchmesser |

d |

L |

Gewicht |

At |

| x Steigung |

mm |

mm |

ca. kg/St. |

mm² |

| Tr 12×3 |

25 |

30 |

0,123 |

739 |

| Tr 14×4 |

30 |

35 |

0,211 |

658 |

| Tr 16×4 |

30 |

35 |

0,199 |

770 |

| Tr 18×4 |

35 |

45 |

0,353 |

1131 |

| Tr 20×4 |

40 |

50 |

0,517 |

1412 |

| Tr 25×5 |

45 |

55 |

0,683 |

1943 |

| Tr 30×6 |

50 |

60 |

0,877 |

2544 |

| Tr 35×6 |

60 |

70 |

1,494 |

3517 |

| Tr 36×6 |

60 |

70 |

1,465 |

3630 |

| Tr 40×7 |

60 |

70 |

1,347 |

4013 |

| Tr 50×8 |

70 |

90 |

2,183 |

6502 |

| Tr 60×9 |

80 |

100 |

2,990 |

8718 |

Werkstoff: EN 1982 Cu Sn12-C – CC483K

Zylindrische Bronzemutter in grossen Abmessungen, auch mit Sondersteigungen. Besonders geeignet als Ersatzteil.

| Durchmesser |

d |

L |

Gewicht |

At |

| x Steigung |

mm |

mm |

ca. kg/St. |

mm² |

| Tr 20×4 |

78 |

60 |

2,43 |

1696 |

| Tr 25×5 |

78 |

75 |

2,96 |

2650 |

| Tr 30×3 |

78 |

90 |

3,30 |

3600 |

| Tr 30×4 |

78 |

90 |

3,31 |

3560 |

| Tr 30×5 |

78 |

90 |

3,32 |

3500 |

| Tr 30×6 |

78 |

90 |

3,33 |

3435 |

| Tr 35×3 |

88 |

105 |

4,85 |

5000 |

| Tr 35×4 |

88 |

105 |

4,86 |

4900 |

| Tr 35×5 |

88 |

105 |

4,87 |

4820 |

| Tr 35×6 |

88 |

105 |

4,89 |

4750 |

| Tr 40×3 |

98 |

120 |

6,80 |

6530 |

| Tr 40×4 |

98 |

120 |

6,82 |

6447 |

| Tr 40×5 |

98 |

120 |

6,83 |

6360 |

| Tr 40×6 |

98 |

120 |

6,85 |

6277 |

| Tr 40×7 |

98 |

120 |

6,87 |

6200 |

| Tr 40×10 |

98 |

120 |

6,91 |

6597 |

| Tr 50×3 |

108 |

150 |

9,74 |

10300 |

| Tr 50×4 |

108 |

150 |

9,77 |

10180 |

| Tr 50×5 |

108 |

150 |

9,79 |

10070 |

| Tr 50×6 |

108 |

150 |

9,82 |

9965 |

| Tr 50×8 |

108 |

150 |

9,87 |

9750 |

| Tr 50×10 |

108 |

150 |

9,92 |

10600 |

| Tr 60×6 |

118 |

180 |

13,29 |

14500 |

| Tr 60×7 |

118 |

180 |

13,32 |

14380 |

| Tr 60×9 |

118 |

180 |

13,36 |

14130 |

Werkstoff: EN 1982 Cu Sn12-C – CC483K

Zylindrische Bronzemutter, geeignet für Bewegungsantriebe mit mässiger Belastung im Vergleich zu den Typen HDL

und HAL. Eine gute Schmierung ist ratsam.

| Durchmesser |

d |

L |

Gewicht |

At |

| x Steigung |

mm |

mm |

ca. kg/St. |

mm² |

| Tr 10×3 |

20 |

20 |

0,044 |

320 |

| Tr 12×3 |

24 |

25 |

0,078 |

412 |

| Tr 14×4 |

24 |

25 |

0,071 |

470 |

| Tr 16×4 |

28 |

30 |

0,118 |

660 |

| Tr 18×4 |

34 |

35 |

0,214 |

880 |

| Tr 20×4 |

38 |

40 |

0,304 |

1130 |

| Tr 25×5 |

44 |

45 |

0,438 |

1590 |

| Tr 30×6 |

48 |

50 |

0,532 |

2120 |

| Tr 35×6 |

58 |

60 |

0,959 |

3015 |

| Tr 36×6 |

58 |

60 |

0,923 |

3110 |

| Tr 40×7 |

64 |

65 |

1,222 |

3727 |

| Tr 45×8 |

68 |

80 |

1,579 |

5152 |

| Tr 50×8 |

74 |

80 |

1,808 |

5780 |

| Tr 55×9 |

78 |

95 |

2,242 |

7535 |

| Tr 60×9 |

84 |

95 |

2,536 |

8282 |

| Tr 70×10 |

98 |

120 |

4,354 |

8742 |

| Tr 80×10 |

108 |

120 |

4,892 |

14137 |

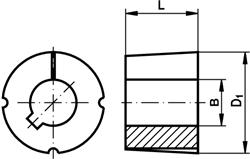

Material: Grauguß

für Keilriemen 16,3 mm bzw. 17 mm

| Typ |

Wirkdurchmesser |

Außendurchmesser |

für Buchse |

MAX Ø |

Gesamtbreite |

| SPB100-2 |

100 |

107 |

1610 |

42 |

44 |

| SPB106-2 |

106 |

113 |

1610 |

42 |

44 |

| SPB112-2 |

112 |

119 |

1610 |

42 |

44 |

| SPB118-2 |

118 |

125 |

1610 |

42 |

44 |

| SPB125-2 |

125 |

132 |

2012 |

50 |

44 |

| SPB132-2 |

132 |

139 |

2012 |

50 |

44 |

| SPB140-2 |

140 |

147 |

2012 |

50 |

44 |

| SPB150-2 |

150 |

157 |

2012 |

50 |

44 |

| SPB160-2 |

160 |

167 |

2012 |

50 |

44 |

| SPB170-2 |

170 |

177 |

2012 |

50 |

44 |

| SPB180-2 |

180 |

187 |

2517 |

60 |

45 |

| SPB190-2 |

190 |

197 |

2517 |

60 |

45 |

| SPB200-2 |

200 |

207 |

2517 |

60 |

45 |

| SPB212-2 |

212 |

219 |

2517 |

60 |

45 |

| SPB224-2 |

224 |

231 |

2517 |

60 |

45 |

| SPB236-2 |

236 |

243 |

2517 |

60 |

45 |

| SPB250-2 |

250 |

257 |

2517 |

60 |

45 |

| SPB280-2 |

280 |

287 |

2517 |

60 |

45 |

| SPB300-2 |

300 |

307 |

2517 |

60 |

45 |

| SPB315-2 |

315 |

322 |

2517 |

60 |

45 |

| SPB335-2 |

335 |

342 |

2517 |

60 |

45 |

| SPB355-2 |

355 |

362 |

3020 |

75 |

51 |

| SPB400-2 |

400 |

407 |

3020 |

75 |

51 |

| SPB450-2 |

450 |

457 |

3020 |

75 |

51 |

| SPB500-2 |

500 |

507 |

3020 |

75 |

51 |

| SPB560-2 |

560 |

567 |

3020 |

75 |

76 |

| SPB630-2 |

630 |

637 |

3020 |

75 |

76 |

Werkstoff: Rostfreier Stahl A1 – AISI 303 – 1.4305

Zylindrisch aus Inox-Stahl AISI 303, besonders korrosionsbeständig gegen chemischen Einflüsse.

| Durchmesser |

d |

L |

Gewicht |

At |

| x Steigung |

mm |

mm |

ca. kg/St. |

mm² |

| Tr 12×3 |

26 |

18 |

0,060 |

297 |

| Tr 14×4 |

30 |

21 |

0,095 |

395 |

| Tr 16×4 |

36 |

24 |

0,157 |

528 |

| Tr 20×4 |

45 |

30 |

0,305 |

847 |

| Tr 24×5 |

50 |

36 |

0,436 |

1215 |

| Tr 30×6 |

60 |

45 |

0,766 |

1908 |

| Tr 36×6 |

75 |

54 |

1,462 |

2799 |

| Tr 40×7 |

80 |

60 |

1,808 |

3440 |

| Tr 50×8 |

90 |

75 |

2,653 |

5418 |

Werkstoff: EN 1982 Cu Sn7 Zn4 Pb7-C – CC493K

Zylindrische Bronzemutter, geeignet für Bewegungsantriebe mit mässiger Belastung im Vergleich zu den Typen FXN,

HDL und HAL. Eine gute Schmierung ist ratsam.

| Durchmesser |

d |

L |

Gewicht |

At |

| x Steigung |

mm |

mm |

ca. kg/St. |

mm² |

| Tr 10×3 |

22 |

20 |

0,057 |

320 |

| Tr 12×3 |

26 |

24 |

0,094 |

396 |

| Tr 14×4 |

30 |

28 |

0,146 |

526 |

| Tr 16×4 |

36 |

32 |

0,245 |

704 |

| Tr 18×4 |

40 |

36 |

0,337 |

905 |

| Tr 20×4 |

45 |

40 |

0,476 |

1130 |

| Tr 22×5 |

45 |

40 |

0,456 |

1225 |

| Tr 24×5 |

50 |

48 |

0,680 |

1620 |

| Tr 26×5 |

50 |

48 |

0,648 |

1770 |

| Tr 28×5 |

60 |

60 |

1,237 |

2400 |

| Tr 30×6 |

60 |

60 |

1,195 |

2544 |

| Tr 32×6 |

60 |

60 |

1,145 |

2733 |

| Tr 36×6 |

75 |

72 |

2,232 |

3732 |

| Tr 40×7 |

80 |

80 |

2,823 |

4587 |

| Tr 44×7 |

80 |

80 |

2,639 |

5090 |

| Tr 50×8 |

90 |

100 |

4,142 |

7224 |

| Tr 60×9 |

100 |

120 |

5,716 |

10462 |

| Tr 70×10 |

110 |

140 |

7,548 |

10200 |

| Tr 80×10 |

120 |

160 |

9,600 |

18850 |

Werkstoff: EN 1982 Cu Sn5 Zn5 Pb5-C – CC491K

Zylindrische Bronzemutter, geeignet für Bewegungsantriebe mit mässiger Belastung im Vergleich zu den Typen FXN,

HDL und HAL. Eine gute Schmierung ist ratsam.

| Durchmesser |

d |

L |

Gewicht |

At |

| x Steigung |

mm |

mm |

ca. kg/St. |

mm² |

| Tr 12×3 |

36 |

36 |

0,302 |

594 |

| Tr 14×4 |

36 |

36 |

0,290 |

677 |

| Tr 16×4 |

36 |

36 |

0,276 |

792 |

| Tr 18×4 |

36 |

36 |

0,259 |

905 |

| Tr 20×4 |

40 |

40 |

0,354 |

1130 |

| Tr 22×5 |

40 |

40 |

0,330 |

1225 |

| Tr 25×5 |

45 |

45 |

0,470 |

1590 |

| Tr 28×5 |

45 |

45 |

0,420 |

1800 |

| Tr 30×6 |

50 |

50 |

0,600 |

2120 |

| Tr 35×6 |

55 |

55 |

0,750 |

2764 |

| Tr 40×7 |

60 |

60 |

0,920 |

3440 |

| Tr 45×8 |

65 |

65 |

1,100 |

4186 |

| Tr 50×8 |

70 |

70 |

1,300 |

5057 |

| Tr 55×9 |

80 |

80 |

2,070 |

6345 |

| Tr 60×9 |

80 |

80 |

1,750 |

6975 |

Werkstoff: EN 10277-3 11 S Mn 30 – 1.0715

Gewindemutter für Spannzwecke und Verstellbewegungen im Handbetrieb bei unbedeutender Belastung, da die

Gleitpaarung Stahl-Stahl unter Belastung zum Anfressen neigt. Das Material ist schweissbar.

| Durchmesser |

d |

L |

Gewicht |

At |

| x Steigung |

mm |

mm |

ca. kg/St. |

mm² |

| Tr 10×3 |

22 |

15 |

0,037 |

240 |

| Tr 12×3 |

26 |

18 |

0,061 |

296 |

| Tr 14×4 |

30 |

21 |

0,095 |

395 |

| Tr 16×4 |

36 |

24 |

0,158 |

528 |

| Tr 18×4 |

40 |

27 |

0,218 |

553 |

| Tr 20×4 |

45 |

30 |

0,308 |

847 |

| Tr 22×5 |

45 |

33 |

0,324 |

1010 |

| Tr 24×5 |

50 |

36 |

0,440 |

1215 |

| Tr 26×5 |

50 |

39 |

0,454 |

1440 |

| Tr 28×5 |

60 |

42 |

0,747 |

1680 |

| Tr 30×6 |

60 |

45 |

0,773 |

1908 |

| Tr 32×6 |

60 |

48 |

0,790 |

2186 |

| Tr 36×6 |

75 |

54 |

1,476 |

2800 |

| Tr 40×7 |

80 |

60 |

1,826 |

3440 |

| Tr 44×7 |

80 |

66 |

1,878 |

4200 |

| Tr 50×8 |

90 |

75 |

2,680 |

5418 |

| Tr 60×9 |

100 |

90 |

3,698 |

7847 |

| Tr 70×10 |

110 |

105 |

4,884 |

10200 |

| Tr 80×10 |

120 |

120 |

6,210 |

14137 |

Werkstoff: EN 10277-3 11 S Mn Pb 37 – 1.0737

Gewindemutter für Spannzwecke und Verstellbewegungen im Handantrieb bei mässiger Belastung, da die Gleitpaarung

Stahl-Stahl zum Anfressen neigt. Das Material ist im Autogen-Verfahren schweissbar (MIG-MAG).

Infolge des Blei-Gehaltes ist das Schweissen mit Elektroden nicht zu empfehlen.

| Durchmesser |

d |

L |

Gewicht |

At |

| x Steigung |

mm |

mm |

ca. kg/St. |

mm² |

| Tr 12×3 |

36 |

36 |

0,26 |

592 |

| Tr 14×4 |

36 |

36 |

0,25 |

677 |

| Tr 16×4 |

36 |

36 |

0,24 |

792 |

| Tr 18×4 |

36 |

36 |

0,22 |

905 |

| Tr 20×4 |

40 |

36 |

0,31 |

1130 |

| Tr 22×5 |

40 |

40 |

0,29 |

1225 |

| Tr 25×5 |

45 |

45 |

0,41 |

1590 |

| Tr 28×5 |

45 |

45 |

0,36 |

1800 |

| Tr 30×6 |

50 |

50 |

0,52 |

2120 |

| Tr 35×6 |

55 |

55 |

0,65 |

2764 |

| Tr 40×7 |

60 |

60 |

0,79 |

3440 |

| Tr 45×8 |

65 |

65 |

0,95 |

4186 |

| Tr 50×8 |

70 |

70 |

1,12 |

5057 |

| Tr 55×9 |

80 |

80 |

1,78 |

6345 |

| Tr 60×9 |

80 |

80 |

1,51 |

6975 |

| für |

Gesamtbreite |

Gesamthöhe |

|

|

Gewicht ca. |

| Kette |

B |

A |

a |

b |

kg/m |

| 06B-1 |

15 |

10 |

1,5 |

5,4 |

0,13 |

| 08B-1 |

20 |

10 |

2,2 |

7,4 |

0,18 |

| 08B-1 |

20 |

15 |

2,2 |

7,4 |

0,26 |

| 08B-1 |

20 |

20 |

2,2 |

7,4 |

0,34 |

| 10B-1 |

20 |

10 |

2,6 |

9,2 |

0,16 |

| 10B-1 |

20 |

15 |

2,6 |

9,2 |

0,25 |

| 10B-1 |

20 |

20 |

2,6 |

9,2 |

0,33 |

| 12B-1 |

25 |

10 |

2,4 |

11,3 |

0,20 |

| 12B-1 |

25 |

15 |

2,4 |

11,3 |

0,32 |

| 12B-1 |

25 |

20 |

2,4 |

11,3 |

0,43 |

| 16B-1 |

40 |

15 |

3,5 |

16,5 |

0,45 |

| 16B-1 |

40 |

20 |

3,5 |

16,5 |

0,68 |

| 20B-1 |

45 |

15 |

4,3 |

19,0 |

0,55 |

| 20B-1 |

45 |

20 |

4,3 |

19,0 |

0,77 |

| 24B-1 |

60 |

15 |

5,6 |

24,6 |

0,67 |

| 24B-1 |

60 |

20 |

5,6 |

24,6 |

0,97 |

| 28B-1 |

75 |

20 |

6,9 |

30,0 |

0,81 |

| 32B-1 |

80 |

20 |

7,8 |

30,0 |

1,11 |

| for |

total width |

total highness |

|

|

weight ca. |

| chain |

B |

A |

a |

b |

kg/m |

| 06B-1 |

15 |

10 |

1,5 |

5,4 |

0,13 |

| 08B-1 |

20 |

10 |

2,2 |

7,4 |

0,18 |

| 08B-1 |

20 |

15 |

2,2 |

7,4 |

0,26 |

| 08B-1 |

20 |

20 |

2,2 |

7,4 |

0,34 |

| 10B-1 |

20 |

10 |

2,6 |

9,2 |

0,16 |

| 10B-1 |

20 |

15 |

2,6 |

9,2 |

0,25 |

| 10B-1 |

20 |

20 |

2,6 |

9,2 |

0,33 |

| 12B-1 |

25 |

10 |

2,4 |

11,3 |

0,20 |

| 12B-1 |

25 |

15 |

2,4 |

11,3 |

0,32 |

| 12B-1 |

25 |

20 |

2,4 |

11,3 |

0,43 |

| 16B-1 |

40 |

15 |

3,5 |

16,5 |

0,45 |

| 16B-1 |

40 |

20 |

3,5 |

16,5 |

0,68 |

| 20B-1 |

45 |

15 |

4,3 |

19,0 |

0,55 |

| 20B-1 |

45 |

20 |

4,3 |

19,0 |

0,77 |

| 24B-1 |

60 |

15 |

5,6 |

24,6 |

0,67 |

| 24B-1 |

60 |

20 |

5,6 |

24,6 |

0,97 |

| 28B-1 |

75 |

20 |

6,9 |

30,0 |

0,81 |

| 32B-1 |

80 |

20 |

7,8 |

30,0 |

1,11 |

| für |

Gesamtbreite |

Gesamthöhe |

|

|

Gewicht ca. |

| Kette |

B |

A |

a |

b |

kg/m |

| 06B-1 |

15 |

10 |

1,5 |

5,4 |

0,13 |

| 08B-1 |

20 |

10 |

2,2 |

7,4 |

0,18 |

| 08B-1 |

20 |

15 |

2,2 |

7,4 |

0,26 |

| 08B-1 |

20 |

20 |

2,2 |

7,4 |

0,34 |

| 10B-1 |

20 |

10 |

2,6 |

9,2 |

0,16 |

| 10B-1 |

20 |

15 |

2,6 |

9,2 |

0,25 |

| 10B-1 |

20 |

20 |

2,6 |

9,2 |

0,33 |

| 12B-1 |

25 |

10 |

2,4 |

11,3 |

0,20 |

| 12B-1 |

25 |

15 |

2,4 |

11,3 |

0,32 |

| 12B-1 |

25 |

20 |

2,4 |

11,3 |

0,43 |

| 16B-1 |

40 |

15 |

3,5 |

16,5 |

0,45 |

| 16B-1 |

40 |

20 |

3,5 |

16,5 |

0,68 |

| 20B-1 |

45 |

15 |

4,3 |

19,0 |

0,55 |

| 20B-1 |

45 |

20 |

4,3 |

19,0 |

0,77 |

| 24B-1 |

60 |

15 |

5,6 |

24,6 |

0,67 |

| 24B-1 |

60 |

20 |

5,6 |

24,6 |

0,97 |

| 28B-1 |

75 |

20 |

6,9 |

30,0 |

0,81 |

| 32B-1 |

80 |

20 |

7,8 |

30,0 |

1,11 |

Trapezgewindespindel

Die Trapezgewindespindel nach DIN ISO 103 werden im Präzisions-Kaltwalzverfahren hergestellt.

Folgende Werkstoffe sind lieferbar:

- EN 10084 CE15E – 1.1141

- EN 10083-2 1C45 – 1.0503

- A2 – AISI 304 – 1.4301 – V2A

- A4 – AISI 316 – 1.4401 – V4A

Kohlenstoffstahl C45 und rostfreier Stahl A2 sind hochwertige Baustähle und weisen nach dem Walzen eine gute Oberflächenhärte und geringe Rauigkeit an den Gewindeflanken auf.

Der rostfreie Stahl A2 zeichnet sich außerdem durch seine gute Korrosionsbeständigkeit aus.

C15 bietet ein hervorragendes Preis-/Leistungsverhältnis.

Die Rauigkeit liegt in allen Fällen unter 1 µm.

Je nach Steigung können die Trapezgewindespindel in Längen von 200 – 6.000 mm geliefert werden.

| Durchmesser |

Außen-Ø |

FlankenØ |

KernØ |

Gewicht |

| x Steigung |

d (min-max) in mm |

d2 (min-max in mm) |

d3 (min-max in mm) |

kg/m |

|

|

|

|

|

| TR10x2 |

9,820 – 10,000 |

8,739 – 8,929 |

7,191 – 7,500 |

0,48 |

| TR10x3 |

9,764 – 10,000 |

8,203 – 8,415 |

6,150 – 6,500 |

0,42 |

| TR12x3 |

11,764 – 12,000 |

10,191 – 10,415 |

8,135 – 8,500 |

0,65 |

| TR14x3 |

13,764 – 14,000 |

12,191 – 12,415 |

10,135 – 10,500 |

0,93 |

| TR14x4 |

13,700 – 14,000 |

11,640 – 11,905 |

9,074 – 9,5000 |

0,86 |

| TR16x4 |

15,700 – 16,000 |

13,640 – 13,905 |

11,074 – 11,500 |

1,17 |

| TR18x4 |

17,700 – 18,000 |

15,640 – 15,905 |

13,074 – 13,500 |

1,53 |

| TR20x4 |

19,700 – 20,000 |

17,640 – 17,905 |

15,074 – 15,500 |

1,94 |

| TR22x5 |

21,665 – 22,000 |

19,114 – 19,394 |

16,044 – 16,500 |

2,29 |

| TR24x5 |

23,665 – 24,000 |

21,094 – 21,394 |

18,019 – 18,500 |

2,78 |

| TR25x3 |

24,764 – 25,000 |

23,165 – 23,415 |

21,103 – 21,500 |

3,30 |

| TR25x5 |

24,665 – 25,000 |

22,094 – 22,394 |

19,019 – 19,500 |

3,05 |

| TR26x5 |

25,665 – 26,000 |

23,094 – 23,394 |

20,019 – 20,500 |

3,33 |

| TR28x5 |

27,665 – 28,000 |

25,094 – 25,394 |

22,019 – 22,500 |

3,92 |

| TR30x5 |

29,665 – 30,000 |

27,094 – 27,394 |

24,019 – 24,500 |

4,57 |

| TR30x6 |

29,625 – 30,000 |

26,547 – 26,882 |

22,463 – 23,000 |

4,38 |

| TR32x6 |

31,625 – 32,000 |

28,547 – 28,882 |

24,463 – 25,000 |

5,06 |

| TR35x5 |

34,665 – 35,000 |

32,094 – 32,394 |

29,019 – 29,500 |

6,40 |

| TR35x6 |

34,625 – 35,000 |

31,547 – 31,882 |

27,463 – 28,000 |

6,16 |

| TR35x8 |

34,550 – 35,000 |

30,493 – 30,868 |

25,399 – 26,000 |

5,85 |

| TR36x6 |

35,625 – 36,000 |

32,547 – 32,882 |

28,463 – 29,000 |

6,56 |

| TR40x5 |

39,665 – 40,000 |

37,094 – 37,394 |

34,019 – 34,500 |

8,51 |

| TR40x6 |

39,625 – 40,000 |

36,547 – 36,882 |

32,463 – 33,000 |

8,26 |

| TR40x7 |

39,575 – 40,000 |

36,020 – 36,375 |

31,431 – 32,000 |

8,03 |

| TR40x8 |

39,550 – 40,000 |

35,493 – 35,868 |

30,399 – 31,000 |

7,90 |

| TR40x10 |

39,470 – 40,000 |

34,450 – 34,850 |

28,350 – 29,000 |

7,49 |

| TR44x7 |

43,575 – 44,000 |

40,020 – 40,375 |

35,431 – 36,000 |

9,90 |

| TR45x8 |

44,550 – 45,000 |

40,493 – 40,868 |

35,399 – 36,000 |

10,23 |

| TR50x5 |

49,665 – 50,000 |

47,094 – 47,394 |

44,019 – 44,500 |

13,70 |

| TR50x6 |

49,625 – 50,000 |

46,547 – 46,882 |

42,463 – 43,000 |

13,35 |

| TR50x8 |

49,550 – 50,000 |

45,468 – 45,868 |

40,368 – 41,000 |

12,90 |

| TR50x10 |

49,470 – 50,000 |

44,425 – 44,850 |

38,319 – 39,000 |

12,37 |

| TR55x9 |

54,500 – 55,000 |

49,935 – 50,360 |

44,329 – 45,000 |

15,51 |

| TR60x6 |

59,625 – 60,000 |

56,547 – 56,882 |

52,463 – 53,000 |

19,67 |

| TR60x7 |

59,575 – 60,000 |

56,020 – 56,375 |

51,431 – 52,000 |

19,36 |

| TR60x9 |

59,500 – 60,000 |

54,935 – 55,360 |

49,329 – 50,000 |

18,74 |

| TR70x10 |

69,470 – 70,000 |

64,425 – 64,850 |

58,319 – 59,000 |

25,80 |

| TR80x10 |

79,470 – 80,000 |

74,425 – 74,850 |

68,319 – 69,000 |

34,39 |

| TR90x12 |

89,400 – 90,000 |

83,335 – 83,830 |

76,246 – 77,000 |

43,07 |

| TR95x16 |

94,290 – 95,000 |

86,250 – 86,810 |

76,100 – 77,000 |

45,90 |

| TR100x12 |

99,400 – 100,000 |

93,330 – 93,830 |

86,215 – 87,000 |

53,99 |

| TR100x16 |

99,290 – 100,000 |

91,250 – 91,810 |

81,110 – 82,000 |

51,37 |

| TR120x14 |

119,330 – 120,000 |

112,290 – 112,820 |

103,157 – 104,000 |

77,72 |

| TR120x16 |

119,290 – 120,000 |

111,250 – 111,810 |

101,110 – 102,000 |

76,34 |

| TR140x14 |

139,330 – 140,000 |

132,290 – 132,820 |

123,157 – 124,000 |

107,87 |

Trapezgewindespindel

The chain puller is availabe in three sizes:

MS 08-12

for roller chains 08B-1 to 12B-1 acc. to DIN 8187

and

for roller chains 08A-1 to 12A-1 acc. to DIN 8188

MS 16-20

for roller chains 16B-1 to 20B-1 acc. to DIN 8187

and

for roller chains 16A-1 to 20A-1 acc. to DIN 8188

MS 24-40

for roller chains 24B-1 to 40B-1 acc. to DIN 8187

and

for roller chains 24A-1 to 40A-1 acc. to DIN 8188

spur gear without hub module 1

- module 1, width B = 15mm

- straight toothing

- angle of pressure 20°

spur gear without hub module 1

|

No. of teeth

|

tip circle

|

pitch circle |

total-

|

pilot bore |

weight |

|

|

Ø |

Ø

|

length

|

Ø

|

approx

|

|

z

|

Dp

|

De

|

B

|

D

|

kg |

|

60

|

62

|

60

|

15

|

12

|

0,20

|

|

70

|

72

|

70

|

15

|

12

|

0,40

|

|

72

|

74

|

72

|

15

|

12

|

0,50

|

|

75

|

77

|

75

|

15

|

12

|

0,50

|

|

76

|

78

|

76

|

15

|

12

|

0,50

|

|

80

|

82

|

80

|

15

|

12

|

0,55

|

|

85

|

87

|

85

|

15

|

12

|

0,70

|

|

90

|

92

|

90

|

15

|

12

|

0,10

|

|

95

|

97

|

95

|

15

|

12

|

0,75

|

|

100

|

102

|

100

|

15

|

12

|

0,90

|

|

110

|

112

|

110

|

15

|

12

|

1,10

|

|

114

|

116

|

114

|

15

|

12

|

1,18

|

|

120

|

122

|

120

|

15

|

12

|

1,40

|

|

127

|

129

|

127

|

15

|

12

|

1,50

|

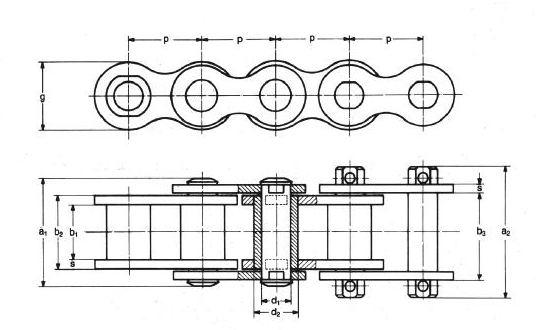

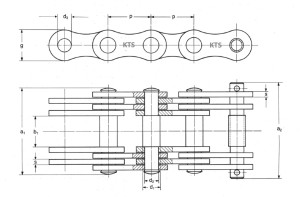

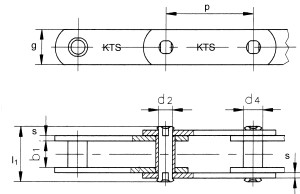

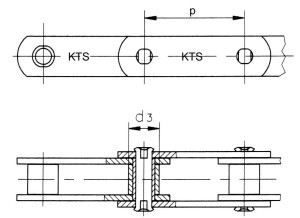

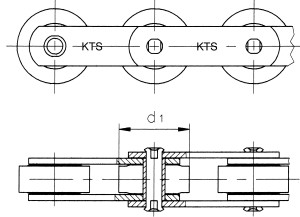

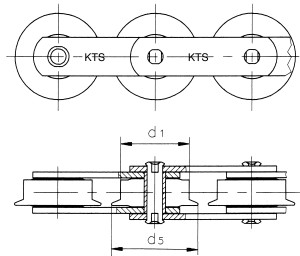

Kettentrenner

Kettentrenner

Für die Entfernung der Lasche am Außenglied einer vernieteten Rollenkette werden schraubbare Kettentrenner verwendet,

mit denen die Kettenbolzen einzeln herausgepreßt werden können.

Den Kettentrenner gibt sie in 2 Größen:

Kettentrenner KT-06-10 für Rollenketten 06B bis 10B nach DIN 8187 bzw. 06C bis 10A nach DIN 8188

(dieser Kettentrenner ist somit auch für Fahrrad- und Motorradketten (auch für X- O- Ringketten) geeignet)

bzw.

Kettentrenner KT-12-20 für Rollenketten 12B bis 20B nach DIN 8187 bzw. 12A bis 20A nach DIN 8188

Screw-type chain breakers can be used to remove the plate on the outside link of a riveted roller chain by pressing the individual pins out.

There are two sizes available:

KT-06-10 for roller chains 06B to 10B acc. to DIN 8187 or 06C to 10A acc. to DIN 8188

and

KT-12-20 for roller chains 12B to 20B acc. to DIN 8187 or 12A to 20A acc. to DIN 8188

Für die Entfernung der Lasche am Außenglied einer vernieteten Rollenkette werden schraubbare Kettentrenner verwendet,

mit denen die Kettenbolzen einzeln herausgepreßt werden können.

Es gibt sie in 2 Größen:

KT-06-10 für Rollenketten 06B bis 10B nach DIN 8187 bzw. 06C bis 10A nach DIN 8188

bzw.

KT-12-20 für Rollenketten 12B bis 20B nach DIN 8187 bzw. 12A bis 20A nach DIN 8188

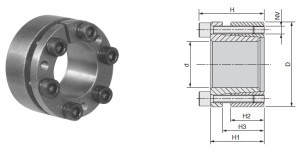

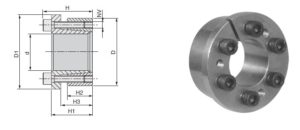

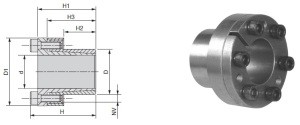

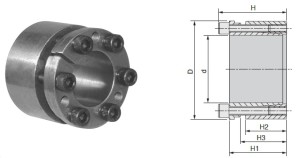

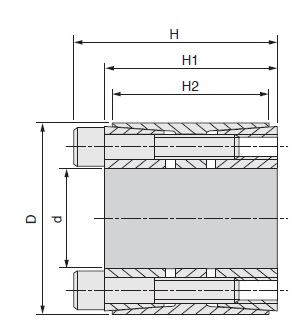

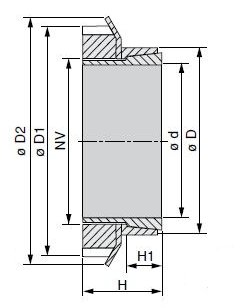

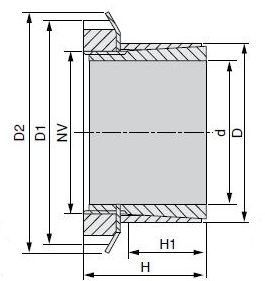

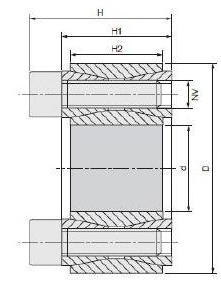

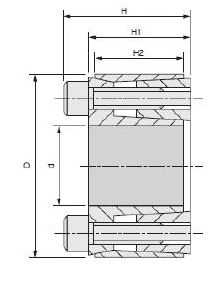

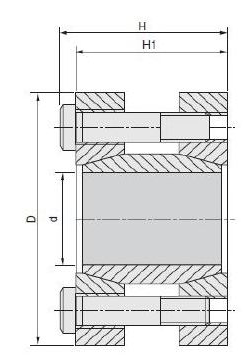

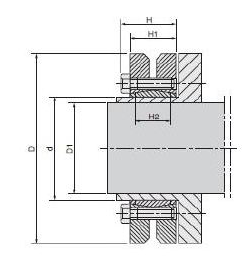

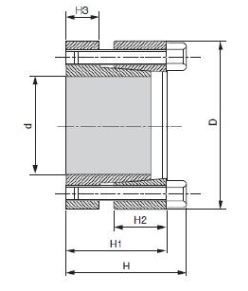

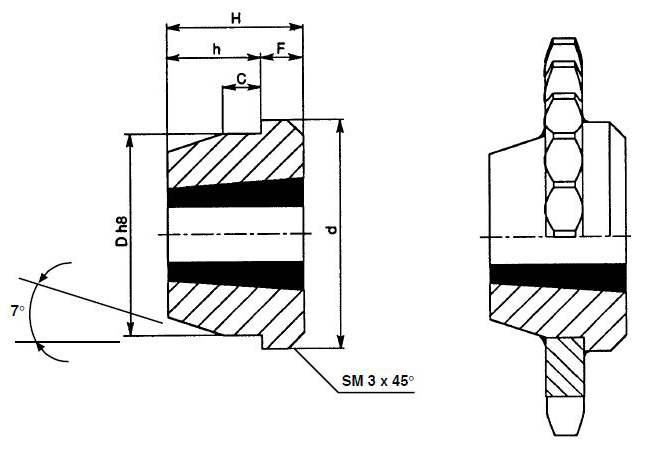

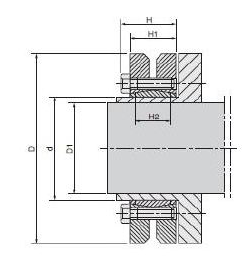

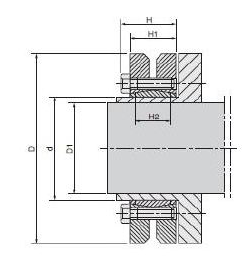

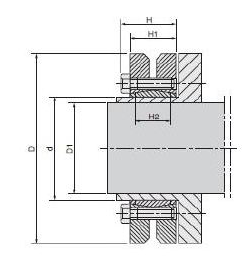

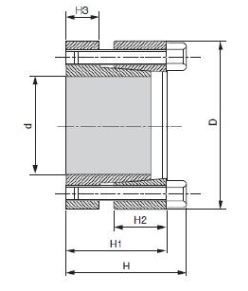

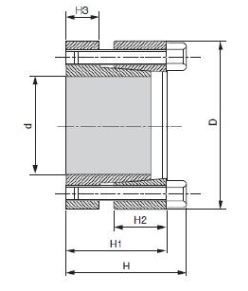

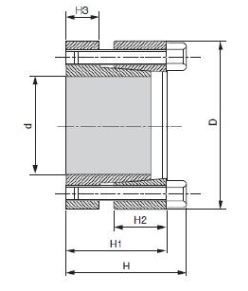

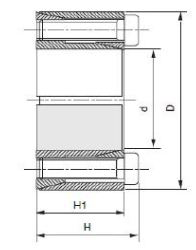

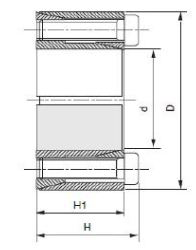

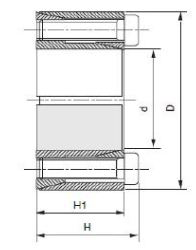

- self-centering

- rapid maintenance and assembly

- for medium-to-high torque

- self-locking

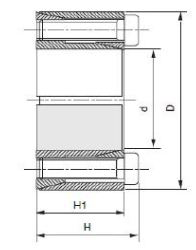

| type |

|

|

|

|

|

|

Performances |

Surface pressures |

|

d |

D |

H3 |

H1 |

H |

H2 |

Mt (Nm) |

Ta (KN) |

| KLAA019 |

19 |

47 |

22 |

28 |

34 |

17 |

355 |

31 |

| KLAA020 |

20 |

47 |

22 |

28 |

34 |

17 |

360 |

33 |

| KLAA022 |

22 |

47 |

22 |

28 |

34 |

17 |

400 |

33 |

| KLAA024 |

24 |

50 |

22 |

28 |

34 |

17 |

440 |

36 |

| KLAA025 |

25 |

50 |

22 |

28 |

34 |

17 |

560 |

36 |

| KLAA028 |

28 |

55 |

22 |

28 |

34 |

17 |

625 |

36 |

| KLAA030 |

30 |

55 |

22 |

28 |

34 |

17 |

650 |

36 |

| KLAA032 |

32 |

60 |

22 |

28 |

34 |

17 |

950 |

50 |

| KLAA035 |

35 |

60 |

22 |

28 |

34 |

17 |

1050 |

50 |

| KLAA038 |

38 |

65 |

22 |

28 |

34 |

17 |

1140 |

50 |

| KLAA040 |

40 |

65 |

22 |

28 |

34 |

17 |

1200 |

50 |

| KLAA045 |

45 |

75 |

25 |

33 |

41 |

20 |

2180 |

70 |

| KLAA050 |

50 |

80 |

25 |

33 |

41 |

20 |

2430 |

85 |

| KLAA055 |

55 |

85 |

25 |

33 |

41 |

20 |

3050 |

85 |

| KLAA060 |

60 |

90 |

25 |

33 |

41 |

20 |

3350 |

85 |

| KLAA065 |

65 |

95 |

25 |

33 |

41 |

20 |

4080 |

85 |

| KLAA070 |

70 |

110 |

30 |

40 |

50 |

24 |

6280 |

119 |

| KLAA075 |

75 |

115 |

30 |

40 |

50 |

24 |

6680 |

119 |

| KLAA080 |

80 |

120 |

30 |

40 |

50 |

24 |

7130 |

119 |

| KLAA085 |

85 |

125 |

30 |

40 |

50 |

24 |

8750 |

132 |

| KLAA090 |

90 |

130 |

30 |

40 |

50 |

24 |

9080 |

132 |

| KLAA095 |

95 |

135 |

30 |

40 |

50 |

24 |

10580 |

132 |

| KLAA100 |

100 |

145 |

32 |

44 |

56 |

26 |

13380 |

170 |

| KLAA110 |

110 |

155 |

32 |

44 |

56 |

26 |

14580 |

170 |

| KLAA120 |

120 |

165 |

32 |

44 |

56 |

26 |

17880 |

200 |

| KLAA130 |

130 |

180 |

40 |

52 |

64 |

34 |

25950 |

270 |

| KLAA140 |

140 |

190 |

40 |

54 |

68 |

34 |

26950 |

270 |

| KLAA150 |

150 |

200 |

40 |

54 |

68 |

34 |

32950 |

320 |

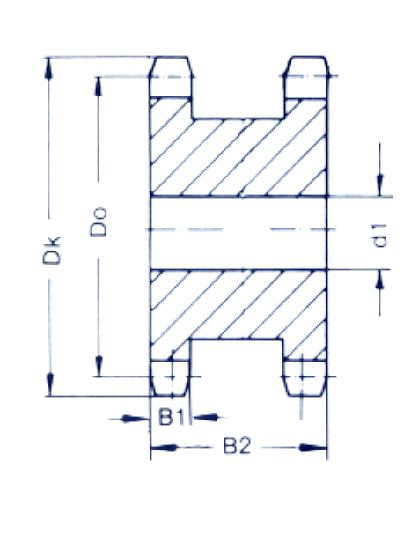

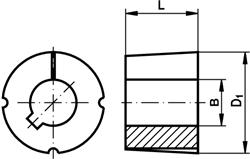

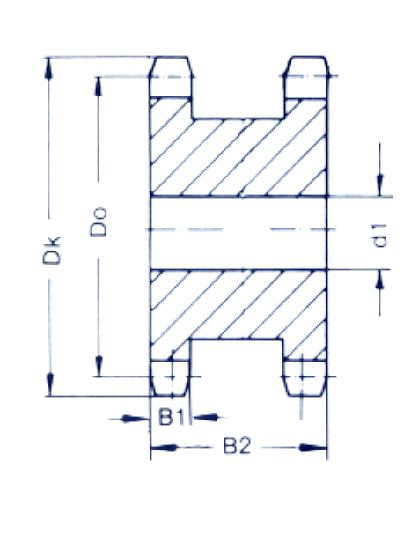

| Article |

no. of teeth |

tip circle |

pitch circle |

tooth width |

total width |

pilot bore |

| no. |

|

|

|

|

|

|

|

z |

Dk |

D0 |

B1 |

B2 |

d1 |

| 1/2″ x 5/16″ |

|

|

|

|

|

|

| DKS-08B-12/12 |

12 |

53,0 |

49,07 |

7 |

28 |

15 |

| DKS-08B-13/13 |

13 |

57,0 |

53,06 |

7 |

28 |

15 |

| DKS-08B-14/14 |

14 |

61,5 |

57,07 |

7 |

28 |

15 |

| DKS-08B-15/15 |

15 |

65,5 |

61,09 |

7 |

28 |

15 |

| DKS-08B-16/16 |

16 |

69,5 |

65,10 |

7 |

28 |

15 |

| DKS-08B-17/17 |

17 |

73,5 |

69,11 |

7 |

28 |

15 |

| DKS-08B-18/18 |

18 |

77,5 |

73,14 |

7 |

28 |

15 |

| DKS-08B-19/19 |

19 |

81,5 |

77,16 |

7 |

28 |

15 |

| DKS-08B-20/20 |

20 |

85,5 |

81,19 |

7 |

28 |

15 |

| DKS-08B-21/21 |

21 |

89,5 |

85,22 |

7 |

28 |

15 |

|

|

|

|

|

|

|

| 5/8″ x 3/8″ |

|

|

|

|

|

|

| DKS-10B-12/12 |

12 |

67,0 |

61,34 |

9 |

36 |

20 |

| DKS-10B-13/13 |

13 |

72,0 |

66,32 |

9 |

36 |

20 |

| DKS-10B-14/14 |

14 |

77,0 |

71,34 |

9 |

36 |

20 |

| DKS-10B-15/15 |

15 |

83,0 |

76,36 |

9 |

36 |

20 |

| DKS-10B-16/16 |

16 |

88,0 |

81,37 |

9 |

36 |

20 |

| DKS-10B-17/17 |

17 |

93,0 |

86,39 |

9 |

36 |

20 |

| DKS-10B-18/18 |

18 |

98,0 |

91,42 |

9 |

36 |

20 |

| DKS-10B-19/19 |

19 |

103,0 |

96,45 |

9 |

36 |

20 |

|

|

|

|

|

|

|

| 3/4″ x 7/16″ |

|

|

|

|

|

|

| DKS-12B-12/12 |

12 |

80,5 |

73,61 |

10,8 |

38 |

20 |

| DKS-12B-13/13 |

13 |

86,5 |

79,59 |

10,8 |

38 |

20 |

| DKS-12B-14/14 |

14 |

92,5 |

85,61 |

10,8 |

38 |

20 |

| DKS-12B-15/15 |

15 |

99,0 |

91,63 |

10,8 |

38 |

20 |

| DKS-12B-16/16 |

16 |

104,5 |

97,65 |

10,8 |

38 |

20 |

| DKS-12B-17/17 |

17 |

111,5 |

103,67 |

10,8 |

38 |

20 |

| DKS-12B-18/18 |

18 |

117,5 |

109,71 |

10,8 |

38 |

20 |

| DKS-12B-19/19 |

19 |

123,0 |

115,75 |

10,8 |

38 |

20 |

|

|

|

|

|

|

|

| 1″ x 17,02 mm |

|

|

|

|

|

|

| DKS-16B-12/12 |

12 |

107,0 |

98,14 |

15,8 |

55 |

25 |

| DKS-16B-13/13 |

13 |

116,0 |

106,12 |

15,8 |

55 |

25 |

| DKS-16B-14/14 |

14 |

123,0 |

114,15 |

15,8 |

55 |

25 |

| DKS-16B-15/15 |

15 |

132,0 |

122,17 |

15,8 |

55 |

25 |

| DKS-16B-16/16 |

16 |

140,0 |

130,20 |

15,8 |

55 |

25 |

| DKS-16B-17/17 |

17 |

148,0 |

138,22 |

15,8 |

55 |

25 |

| für |

Gesamtbreite |

Gesamthöhe |

|

|

|

Gewicht ca. |

| Kette |

B |

A |

b |

a |

c |

kg/m |

| 06B-2 |

25 |

10 |

5,4 |

1,5 |

15,74 |

0,22 |

| 08B-2 |

35 |

10 |

7,4 |

2,2 |

21,42 |

0,30 |

| 08B-2 |

35 |

15 |

7,4 |

2,2 |

21,42 |

0,46 |

| 08B-2 |

35 |

20 |

7,4 |

2,2 |

21,42 |

0,63 |

| 10B-2 |

40 |

10 |

9,2 |

2,6 |

25,79 |

0,32 |

| 10B-2 |

40 |

15 |

9,2 |

2,6 |

25,79 |

0,54 |

| 10B-2 |

40 |

20 |

9,2 |

2,6 |

25,79 |

0,77 |

| 12B-2 |

45 |

15 |

11,3 |

2,4 |

30,76 |

0,62 |

| 12B-2 |

45 |

20 |

11,3 |

2,4 |

30,76 |

0,85 |

| 16B-2 |

65 |

15 |

16,5 |

3,5 |

48,38 |

0,86 |

| 16B-2 |

65 |

20 |

16,5 |

3,5 |

48,38 |

1,19 |

| 20B-2 |

70 |

15 |

19,0 |

4,3 |

54,45 |

0,89 |

| 20B-2 |

70 |

20 |

19,0 |

4,3 |

54,45 |

1,22 |

| 24B-2 |

88 |

20 |

24,6 |

5,6 |

72,96 |

1,48 |

| 28B-2 |

105 |

25 |

30,0 |

6,9 |

89,56 |

1,75 |

| 32B-2 |

105 |

30 |

30,0 |

7,8 |

88,55 |

2,10 |

| for |

total width |

total highness |

|

|

|

weight ca. |

| chain |

B |

A |

b |

a |

c |

kg/m |

| 06B-2 |

25 |

10 |

5,4 |

1,5 |

15,74 |

0,22 |

| 08B-2 |

35 |

10 |

7,4 |

2,2 |

21,42 |

0,30 |

| 08B-2 |

35 |

15 |

7,4 |

2,2 |

21,42 |

0,46 |

| 08B-2 |

35 |

20 |

7,4 |

2,2 |

21,42 |

0,63 |

| 10B-2 |

40 |

10 |

9,2 |

2,6 |

25,79 |

0,32 |

| 10B-2 |

40 |

15 |

9,2 |

2,6 |

25,79 |

0,54 |

| 10B-2 |

40 |

20 |

9,2 |

2,6 |

25,79 |

0,77 |

| 12B-2 |

45 |

15 |

11,3 |

2,4 |

30,76 |

0,62 |

| 12B-2 |

45 |

20 |

11,3 |

2,4 |

30,76 |

0,85 |

| 16B-2 |

65 |

15 |

16,5 |

3,5 |

48,38 |

0,86 |

| 16B-2 |

65 |

20 |

16,5 |

3,5 |

48,38 |

1,19 |

| 20B-2 |

70 |

15 |

19,0 |

4,3 |

54,45 |

0,89 |

| 20B-2 |

70 |

20 |

19,0 |

4,3 |

54,45 |

1,22 |

| 24B-2 |

88 |

20 |

24,6 |

5,6 |

72,96 |

1,48 |

| 28B-2 |

105 |

25 |

30,0 |

6,9 |

89,56 |

1,75 |

| 32B-2 |

105 |

30 |

30,0 |

7,8 |

88,55 |

2,10 |

| für |

Gesamtbreite |

Gesamthöhe |

|

|

|

Gewicht ca. |

| Kette |

B |

A |

b |

a |

c |

kg/m |

| 06B-2 |

25 |

10 |

5,4 |

1,5 |

15,74 |

0,22 |

| 08B-2 |

35 |

10 |

7,4 |

2,2 |

21,42 |

0,30 |

| 08B-2 |

35 |

15 |

7,4 |

2,2 |

21,42 |

0,46 |

| 08B-2 |

35 |

20 |

7,4 |

2,2 |

21,42 |

0,63 |

| 10B-2 |

40 |

10 |

9,2 |

2,6 |

25,79 |

0,32 |

| 10B-2 |

40 |

15 |

9,2 |

2,6 |

25,79 |

0,54 |

| 10B-2 |

40 |

20 |

9,2 |

2,6 |

25,79 |

0,77 |

| 12B-2 |

45 |

15 |

11,3 |

2,4 |

30,76 |

0,62 |

| 12B-2 |

45 |

20 |

11,3 |

2,4 |

30,76 |

0,85 |

| 16B-2 |

65 |

15 |

16,5 |

3,5 |

48,38 |

0,86 |

| 16B-2 |

65 |

20 |

16,5 |

3,5 |

48,38 |

1,19 |

| 20B-2 |

70 |

15 |

19,0 |

4,3 |

54,45 |

0,89 |

| 20B-2 |

70 |

20 |

19,0 |

4,3 |

54,45 |

1,22 |

| 24B-2 |

88 |

20 |

24,6 |

5,6 |

72,96 |

1,48 |

| 28B-2 |

105 |

25 |

30,0 |

6,9 |

89,56 |

1,75 |

| 32B-2 |

105 |

30 |

30,0 |

7,8 |

88,55 |

2,10 |

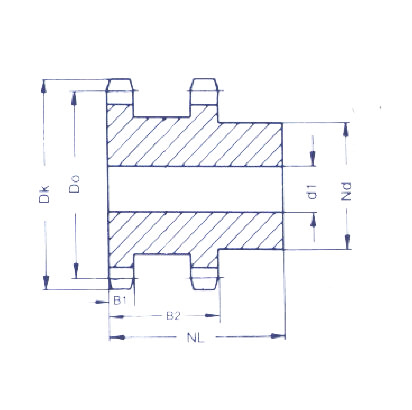

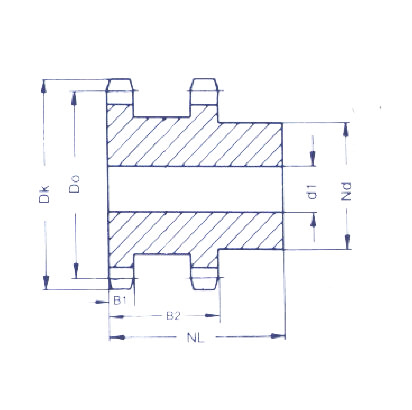

| article |

No. of teeth |

pitch circle |

tip circle |

Tooth width |

total |

hub- |

total |

pilot bore |

| no. |

|

|

|

|

tooth width |

dia. |

length |

|

| |

z |

Dk |

D0 |

B1 |

B2 |

Nd |

NL |

d1 |

| size 1/2″ x 5/16″ |

|

|

|

|

|

|

|

|

| DKR-08B-12/12 |

12 |

53,0 |

49,07 |

7 |

28 |

35 |

44 |

15 |

| DKR-08B-13/13 |

13 |

57,0 |

53,06 |

7 |

28 |

38 |

44 |

15 |

| DKR-08B-14/14 |

14 |

61,5 |

57,07 |

7 |

28 |

42 |

44 |

15 |

| DKR-08B-15/15 |

15 |

65,5 |

61,09 |

7 |

28 |

46 |

44 |

15 |

| DKR-08B-16/16 |

16 |

69,5 |

65,10 |

7 |

28 |

50 |

44 |

15 |

| DKR-08B-17/17 |

17 |

73,5 |

69,11 |

7 |

28 |

54 |

44 |

15 |

| DKR-08B-18/18 |

18 |

77,5 |

73,14 |

7 |

28 |

58 |

44 |

15 |

| DKR-08B-19/19 |

19 |

81,5 |

77,16 |

7 |

28 |

62 |

44 |

15 |

| DKR-08B-20/20 |

20 |

85,5 |

81,19 |

7 |

28 |

66 |

44 |

15 |